Products

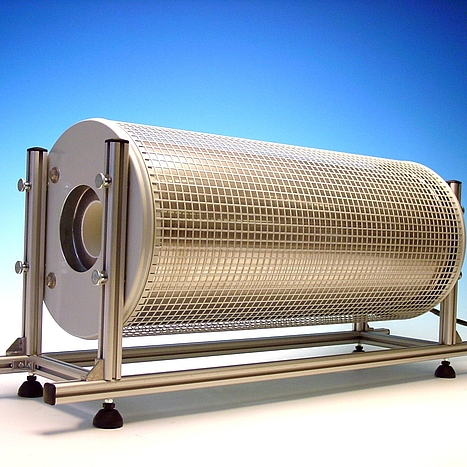

HMF - Tube Furnaces for Operating Temperatures 50 °C - 1000 °C

Horst tube furnaces are made of standardized components according to customer's requirements. Each appliance is constructed considering the individual technical demands.

Examples:

• standard desktop model with detachable stand and protective barrier

• reactor heating, integrated in a production plant or test set-up

• three-part tube furnace on a sliding rail

• heating in portable calibrating devices

• built-in model for 19" casings

• stationary model for use in combination with eight inserted furnaces, water-cooled to minimize heat radiation

• hinged furnace with glass fabric heating surface

All tube furnaces provide short heating-up times and homogenous heat distribution. This is achieved by using electrically-insulated heating conductors, which allow a narrow winding round the tube. The total power is distributed on the longest possible heating conductor in order to keep the surface load low.

Each tube furnace can be used in a vertical or horizontal position and has a built-in thermocouple.

Tube furnaces must be used in combination with a temperature regulator. You can either use an available control device or choose a matching regulator from our product range, e.g. HT 30 or HT MC11 .

For a quotation, please let us have a description of the application and the following specifications according to the options.

Options

| inner tube diameter | 3 - 120 mm |

| inner tube material | heat-resistant stainless steel, quartz glass, ceramics |

| heated length | 50 - 1000 mm |

| operating temperature | 50 °C - 1000 °C, max. 800 °C with metallic inner tubes |

| temperature sensor | NiCr-Ni, Pt 100, others |

| heating zones | as required, depending on the heated length |

| nominal voltage | 12 - 400 VAC |